What are the tips for using the automatic imager

-

2020-12-25

2020-12-25 -

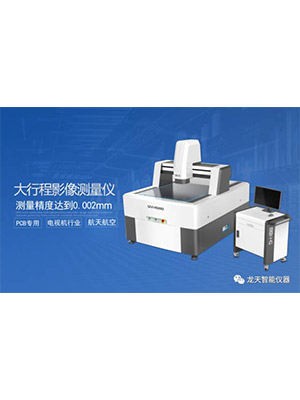

The automatic image measuring instrument is based on the artificial intelligence technology of automatic margin extraction, automatic focusing, measurement synthesis, image synthesis, etc. based on machine vision. It has automatic measurement, CNC positioning automatic measurement, automatic learning batch measurement, image map target guidance, and Features such as eagle eye zoom in the field of view. Next, our Longtian Intelligent Instrument will tell you about some tips.

At the same time, it is based on the autofocus process under the precise control of machine vision and micron, which can meet the needs of auxiliary height measurement under clear contrast. It supports the software performance of spatial coordinate rotation, can perform batch measurement when the workpiece is placed at will, and can also use the fixture to perform mass scanning measurement and SPC result classification. The following editor will introduce to you what are the tips for using the automatic imager.

Tips for using the automatic image measuring instrument:

1. Before the workpiece is hoisted, the probe should be returned to the original point to reserve a larger space for the hoisting position; the workpiece should be hoisted smoothly, and no component of the image measuring instrument should be hit.

2. Install the parts correctly and ensure that they meet the isothermal requirements of the parts and the measuring machine before installation.

3. Establish a correct coordinate system and ensure that the coordinate system built meets the requirements of the drawing, so as to ensure the accuracy of the measured data.

4. Before the workpiece is hoisted, the probe should be returned to the original point to reserve a large space for the hoisting position; the workpiece should be hoisted smoothly, and no component of the image measuring instrument should be hit. When the program is programmed to run automatically, it is necessary to prevent the probe from interfering with the workpiece, so pay attention to increasing the inflection point.

5. For some large and heavier molds and inspection tools, the workbench should be hung down in time after the measurement to avoid the image measuring instrument workbench from being in the load state for a long time.

Accuracy is the soul of precision measuring instruments. If accuracy cannot be guaranteed, the instrument will lose its value. Two-dimensional image measuring instruments are no exception, and the correct operation method is the key to ensuring the two-dimensional image instrument.